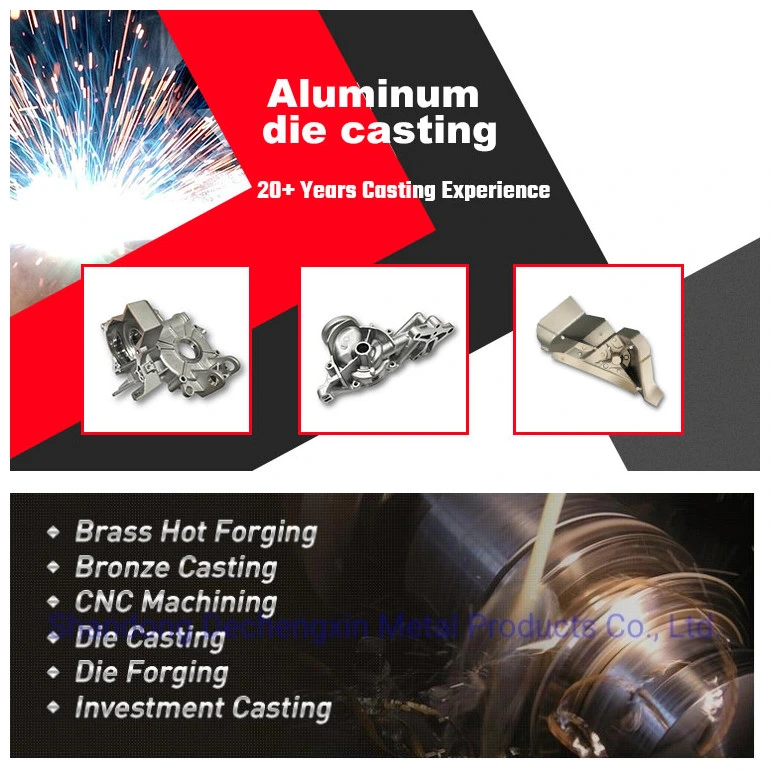

OEM di pezzi meccanici per colata a pressione in lega di zinco/zama di pressofusione di alluminio

L'OEM dei pezzi meccanici della pressofusione di alluminio/lega di zinco/lega di zama della pressofusione

Invia la tua richiestaDESCRIZIONE

Informazioni basilari.

| Modello numero. | ODM/OEM |

| Attrezzatura | Macchina per pressofusione a camera fredda |

| Assistenza software | PRO-E/Solid Work/E/Auto CAD/Catia |

| Superficie | Rifilatura, sbavatura, lucidatura |

| Pacchetto di trasporto | Mare, Aria, Treno |

| Specifica | Lega di alluminio |

| Marchio | DCX |

| Origine | Cina |

| Codice SA | 7217100000 |

| Capacità produttiva | 1000 tonnellate/tonnellate al mese |

Descrizione del prodotto

OEM di pezzi meccanici per pressofusione di alluminio/lega di zinco/zamak

>>Dettagli Immagini:

1. Elevata capacità di carico e precisione; 2. Resistenza all'usura e alla corrosione; 3. Elevata conduttività termica; 4. Buona fluidità e plasticità; >> Applicazione:

>>Produzione leggera di alluminio--Colata a pressione

Abbiamo sviluppato con successo il processo di squeeze casting. Dopo il trattamento T6, le parti avranno lo stesso livello di resistenza e durezza della forgiatura, ma non avranno bisogno di molti lavori di lavorazione meccanica, quindi alla fine si realizzeranno l'elevata resistenza e la leggerezza della produzione.

>>Procedure di fusione a compressione:

| Processi | Pressofusione di alluminio, pressofusione a compressione + T6, pressofusione in lega di zinco, lavorazione CNC, tornitura |

| Attrezzatura | Macchina per pressofusione a camera fredda: centri 200T/280T/400T/600T/800T/1100T.CNC, tornitura CNC, torni CNC, impulso elettrico, taglio in linea, fresatura, foratura, rettifica |

>CNC Equipment:/pAs a manufacturer, it is a great advantage to have our own moulds workshop, to make the perfect parts by saving time and costs. Set with full machines and skilled team, we can finish moulds very quickly for some big project with more than 50 models of parts. And changing or testing new samples always are free to customer and to be finished within short time.br>

>Production Equipments:brFull equipments support us the enough production capacity. We can make a wide range of parts from 0.01kg ~ 20kg. We can offer a very short lead time for you and adjust our production shifts according to customers urgent needs.br>

>Process Introduction:br-Integrated the advantages of forging and die casting.-Parts forming under vacuum & high pressure conditions.-Parts are made with very high density, very strong strength & hardness after T6.-Roughness of parts are as same as the die casting.-Precision with no more machining for some complex structurebr>> Technical Data Sheet:table border="1" cellpadding="1" cellspacing="1">

>Professional Design&Manufacturing:br>>Hot Products:br>

>Why Choose Us?br1. Own mould R&D team and mould making workshop.2. Own factory to offer the reasonable prices and quick response.3. Complete service from mould, production, heat treatment, surface treatment, assemble.4. 20years experience for die casting.5. Squeeze casting+T6 -- to make the parts with lightweight and strong strength.br>>OEM Service:br>>Company Profile:brShandong (Qingdao) Dechengxin Metal Products Co., Ltd is specialized in the production of aluminum die casting, zinc alloy die casting, and aluminum lightweight production. Since establish of 2006, we always provide the best die casting parts to customers, and now we also develop the lightweight process successfully and obtain many national patents. Our products are widely used in automobile, medical, power Industry, electrical appliance, construction, high-speed railway and so on. And we have exported to Japan, Germany, USA, Canada, Australia and many countries.1.)Great advantages as a manufacturerFirstly, we have fixed material partner supplying us the good quality original material and assistant us to research & develop new material. Secondly, we have our own design and production team of moulds/tooling, which is very cost-effective for moulds/tooling change or optimize. Finally we can offer Supply Chain Service with time & costs saved from design, casting, precision CNC machining, finishing to the final assembled products with shipment service to you.2.)Aluminum Lightweight ProductionWe have developed the process of squeeze casting and new material Al-Ti alloy successfully. After T6 treatment, parts will be same level of strength and hardness as forging, but not need so much machining jobs, then finally realized the high strength and light weight of production. With excellent mechanical property, costs saving, extremely good surface finish, squeeze casting will be your best choice in place of ordinary processes like sand casting, extrusion, forging and others.3.)Environmental Impact Assessment & ISO 9001 CertifiedSelecting a reliable and qualified partner is more different & difficult than just choosing a supplier. We have obtained the license of EIA from government and get certied of ISO 9001, and we will always process our production per as EIA & ISO requirement strictly, to guarantee the stable production, to supply the qualified parts to you and enlarge your business finally. We sincerely hope we can become your faithful partner and develop a flouring future with you.br>

>Package&Shipment:br>>Strict Quality Control:br>>Certificates:br>>FAQ:brQ.1:Can we get your free samples? A. For the samples in our stocksize, sure, we'd love to provide you for free to test the quality, but hope you can bear the Freight cost.B. For the customized samples, we can also open a new mould as your requests, but hope you can bear this samples cost. Q.2:What is the normal lead time?A. For stock products, we will send goods to you within 1~7days after receiving your payment.B. For mass production, lead time is around 30~40days, and longer if need open new mould.brQ.3: What shipping tools you use for different orders shipment?br>A. For small trial order,FEDEX, DHL, UPS, TNT etc can be provided.B. For larger order,we can arrange shipment by sea or by air according to your requirement.

Prodotti correlati

-

![Pressofusione di prodotti in lega di alluminio di precisione personalizzata per fusione di alluminio ad alta pressione]()

Pressofusione di prodotti in lega di alluminio di precisione personalizzata per fusione di alluminio ad alta pressione

-

![Generatore eolico Real Watt 5kw 240V Sistema eolico 5000W Asse orizzontale]()

Generatore eolico Real Watt 5kw 240V Sistema eolico 5000W Asse orizzontale

-

![Offerte mensili Parti di stampi ad iniezione Utensili per stampi e molle di azoto per bombole di gas di azoto Molle a gas per stampi per pressofusione]()

Offerte mensili Parti di stampi ad iniezione Utensili per stampi e molle di azoto per bombole di gas di azoto Molle a gas per stampi per pressofusione

-

![Parti di automazione per lavorazione CNC in acciaio inossidabile in lega di alluminio per fresatura di ottone in metallo]()

Parti di automazione per lavorazione CNC in acciaio inossidabile in lega di alluminio per fresatura di ottone in metallo